LORD Corporation

With more than 3,100 employees in 26 countries, 19 manufacturing facilities and 10 R&D centers worldwide, we're there for our customers.

Our Company

-

Products and Solutions

To speak to someone directly, call

Customer Support:

8AM–5PM EST

Technical Support:

8AM–5PM EST

-

Industries

To speak to someone directly, call

Customer Support:

8AM–5PM EST

Technical Support:

8AM–5PM EST

-

Our Company

To speak to someone directly, call

Customer Support:

8AM–5PM EST

Technical Support:

8AM–5PM EST

-

Feedback Button

Feedback Button

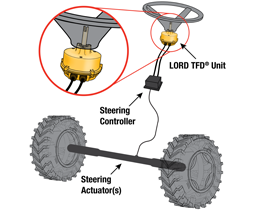

Electro-hydraulic and fully-electric Steer-by-Wire (SbW) systems are gaining favor over traditional mechanical and hydraulic steering systems. Vehicles with SbW systems tend to consume less energy, which reduces the cost of ownership and improves environmental impact. In SbW systems there is no mechanical connection between the steering wheel and road wheels, which has challenged OEMs in providing the operator with a high quality steering feel. In response to this challenge LORD offers a line of Tactile Feedback Device (TFD) steering units.

What is a Tactile Feedback Device?

The Tactile Feedback Device (TFD) steering unit is a key component of fully-electric and electro-hydraulic SbW systems. These devices provide an integrated solution that combines bearing support, steering position sensing, communication and continuously variable resistive steering torque, all to deliver high-fidelity tactile feedback (the steering "feel") and maximum control to the operator.

The Tactile Feedback Device (TFD) steering unit is a key component of fully-electric and electro-hydraulic SbW systems. These devices provide an integrated solution that combines bearing support, steering position sensing, communication and continuously variable resistive steering torque, all to deliver high-fidelity tactile feedback (the steering "feel") and maximum control to the operator.

How Does a TFD Work?

The TFD steering unit is typically mounted below the vehicle’s steering wheel. As the operator turns the steering wheel, the hall-effect steering sensor detects and transmits the steering position to the vehicle steering controller. The steering controller uses information from a variety of vehicle inputs to determine the preferred steering response.

The steering response can be programmed for partial or multiple rotations, to be speed sensitive, and to generate end-stop control, position detents and more. Integration with other devices and technologies, such as electric motors, GPS and vision systems, can provide sophisticated hybrid steering control.

Torque feedback to the operator is generated through our proprietary “Direct Shear Mode” design, in which a rotor attached to a shaft shears magnetically responsive (MR) material against a fixed stator. As the current commanded by the vehicle steering controller to the TFD steering unit changes, a lowpower (0-1 amp) coil generates a magnetic field that instantaneously changes the properties of the MR material and the subsequent torque feedback.

With torque feedback independent of speed and temperature, a wide variety of applications can benefit from the smooth and quiet steering feel.

Where are TFDs Used?

LORD has been a pioneer in SbW steering units since 1999, when the first device began production on a forklift truck application. With more than half a million devices in the field today, LORD Corporation has a long history of providing reliable and safe TFD steering units to OEMs in various markets including: Marine (Helm Controls), Material Handling (Forklifts), Turf (Greens Mowers), Off-Highway (Agricultural Tractors and Construction Equipment) and Small Industrial Vehicles (Floor Sweepers, Zamboni, Etc.).

Benefits and Advantages of Tactile Feedback Devices

Attribute

Advantage

Proportional Torque Control

High

Control Fidelity

High

Temperature Sensitivity

No

Power Requirements

Low

Device Size

Small

Implementation Cost

Low

- Improved Steering Feedback Performance

- Programmable resistive steering feedback based on equipment operating conditions

- Smooth Steering Torque Independant of Vehicle Speed and Temperature

- No "Stick Slip" at Low Speeds (Common with Friction Brakes)

- No Electric Motor "Cogging" Feel

- Increased Ease of Off-Road Maneuverability

- Improved Accuracy at On-Road Speeds

- Low Power Consumption

- Fast Response Time

- Reliable Control Signals

- Multiple Non-Contact Sensor Configurations (2, 3, or 4 Outputs)

- Analog (v) and/or Digital (pwm) Outputs

- Protected from EMC

- SIL2/3 Safety Rating (SIL = Safety Integrity Level)

- Increased Design Flexibility

- Extensive Portfolio of Standard and Customized Solutions

- Robust, Easy-to-Install, Compact Design

- Improved Steering Ergonomics for the Operator

- No Maintenance Required

Videos - Learn More and See TFDs in Action