We're constantly innovating new belt bonding adhesive solutions. From the latest industry advancements like Belt-in-Oil (BIO), our solutions enable and improve automotive belting technology.

LORD Corporation

With more than 3,100 employees in 26 countries, 19 manufacturing facilities and 10 R&D centers worldwide, we're there for our customers.

Our Company

-

Products and Solutions

To speak to someone directly, call

Customer Support:

8AM–5PM EST

Technical Support:

8AM–5PM EST

-

Industries

To speak to someone directly, call

Customer Support:

8AM–5PM EST

Technical Support:

8AM–5PM EST

-

Our Company

To speak to someone directly, call

Customer Support:

8AM–5PM EST

Technical Support:

8AM–5PM EST

-

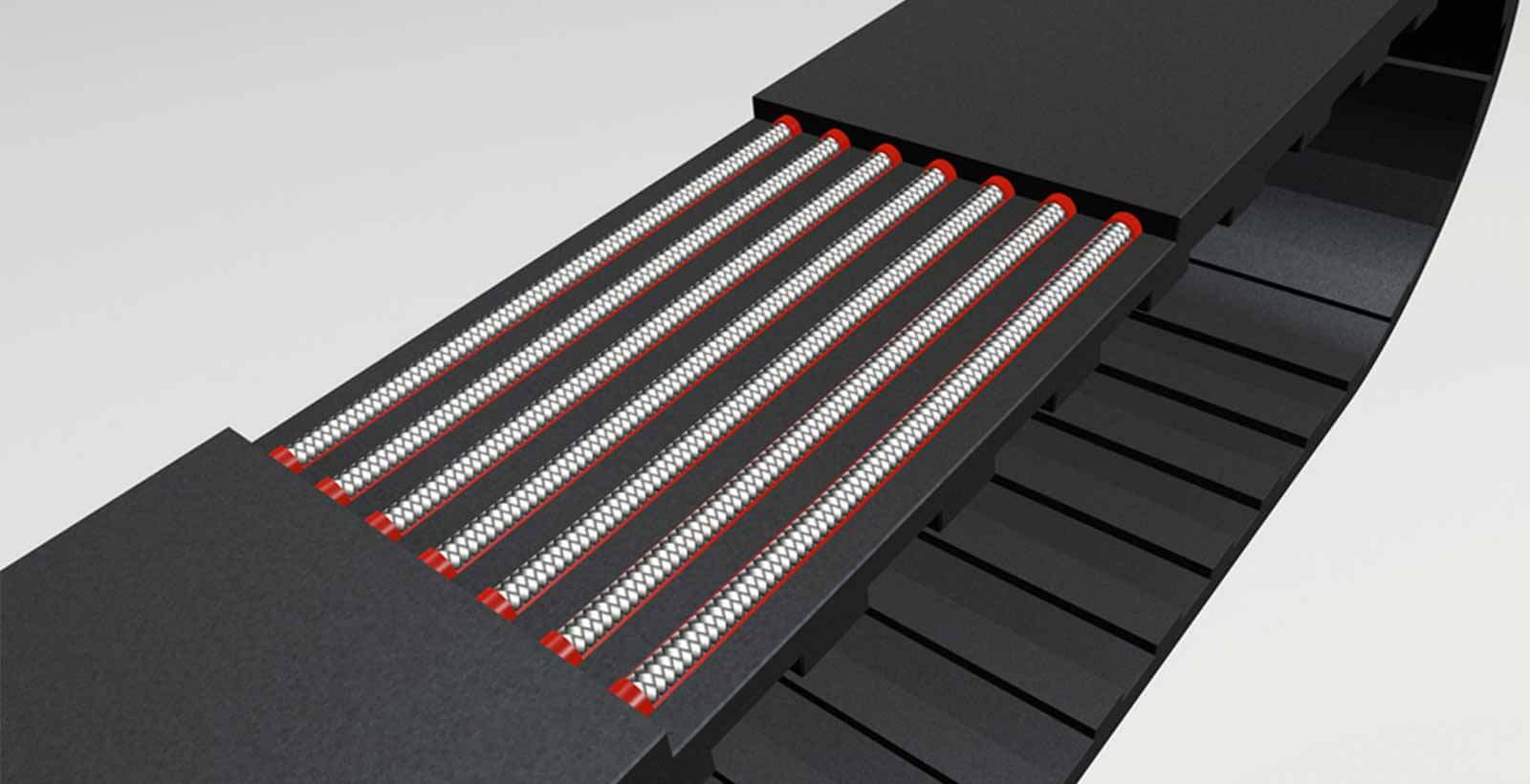

Belt Bonding Adhesives

We offer adhesives for belts that can withstand high temperatures and harsh environments.Discuss your application with one of our experts who can recommend the best solution.

Adhesives for Belt Manufacturing

Automotive Belts | Serpentine Belts | Belt-in-Oil | Timing Belts | Accessory Belts | Conveyor Belts | V-Belts

Our Chemlok® adhesives are backed by our global support system and built on elastomer bonding technology that has generations of proven performance. When bonding to metal, fabric or countless other materials, LORD Chemlok high performance rubber-to-substrate adhesives are the ultimate choice.

Automotive Timing & Serpentine Belts

Material Handling & Conveyor Belts

From manufacturing and assembly to patch and repair, our portfolio of Chemlok® rubber bonding adhesives includes solutions that cover the entire conveyor belt life cycle.

Industrial Power Transmission Belts

Reliable power transmission belts are essential to keeping critical equipment up and running. Up time and productivity are vital, even in the harshest of applications like mining machinery, off-highway equipment and heavy-duty trucks. Our adhesives form durable bonds, enabling reliable belts.